• Initiates AI autonomous manufacturing platform to optimize processes and reduce greenhouse gas emissions

• Recognized with Minister of Trade, Industry, and Energy Award for contributions to digital transformation through AI-based process optimization

GS Caltex is embarking on the development of an AI autonomous manufacturing platform aimed at optimizing refining and petrochemical processes while reducing greenhouse gas emissions.

The company announced on the 13th that it is advancing the “AI Autonomous Manufacturing Platform” initiative as part of the Ministry of Trade, Industry, and Energy’s (MOTIE) national strategic project, the “AI Autonomous Manufacturing Leading Project.”

AI autonomous manufacturing refers to an advanced production environment where AI technology integrates with robots and equipment to enhance automation and optimization. This approach enables a shift from low-variety, traditional mass production to a more customized, multi-product manufacturing system. Additionally, AI-driven real-time data analysis helps monitor equipment conditions, predict failures, and conduct preventive maintenance, ultimately boosting productivity.

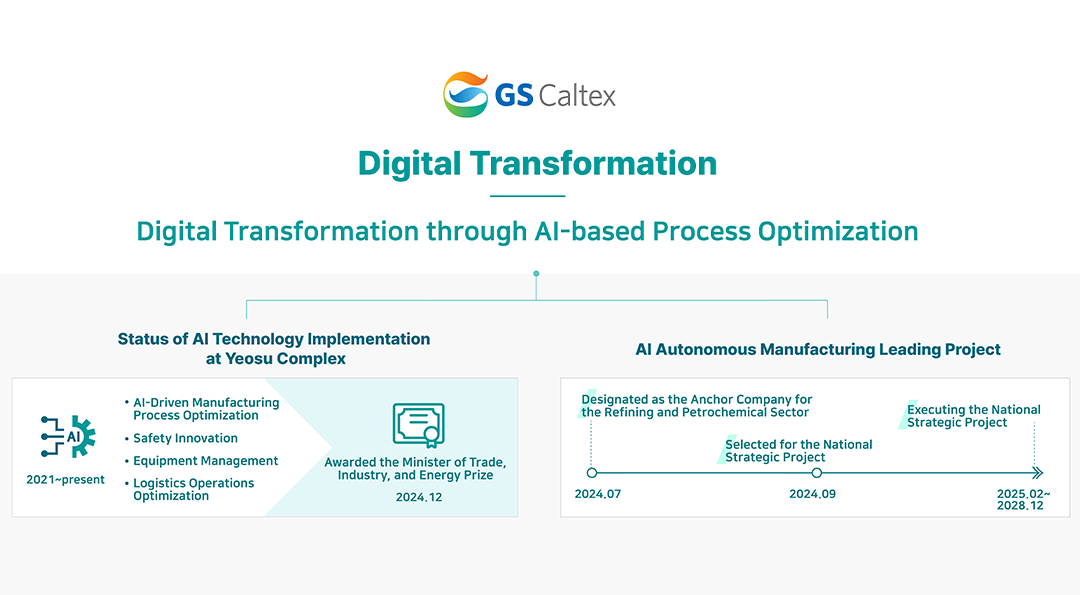

To strengthen the competitiveness of domestic manufacturing, MOTIE introduced the “AI Autonomous Manufacturing Strategy 1.0” in May last year and launched the “AI Autonomous Manufacturing Alliance” in July. The alliance consists of 12 key industrial sectors in South Korea, with GS Caltex designated as the anchor company for the petrochemical sector.

Moreover, GS Caltex submitted a proposal titled “Development of AI Autonomous Manufacturing Platform for Process Optimization and Greenhouse Gas Reduction in the Refining and Petrochemical Industry” to MOTIE’s open call for the AI Autonomous Manufacturing Leading Project. The proposal was selected last September, and following a preparation phase, the project officially commenced this month.

The initiative is a collaborative effort involving GS Caltex, the Korea Institute of Industrial Technology (KITECH), Pusan National University, Kyung Hee University, Hanyang University, Jeollanam-do Province, and Yeosu City, with MOTIE providing approximately KRW 8 billion in funding. GS Caltex is responsible for developing and demonstrating the AI autonomous manufacturing platform. Once implemented, the platform will enable real-time process data analysis to optimize overall operations, enhance efficiency, and reduce greenhouse gas emissions.

The project will run through the end of 2028 in two phases. In the first phase, operational data from refining and petrochemical processes will be collected and analyzed to develop AI optimization models for individual processes. In the second phase, these models will be integrated into a comprehensive AI autonomous manufacturing platform, which will be demonstrated and refined at the Yeosu plant.

Refining and petrochemical processes generate vast amounts of real-time data and involve complex interdependencies among continuous operations. Due to these characteristics, traditional manual decision-making by experienced operators has limitations in achieving full-scale optimization. GS Caltex plans to develop AI models that analyze correlations between key variables such as raw material input, product specifications and yield, and CO2 emissions. These models will establish optimal operational strategies.

Additionally, the company will expand its AI-driven digital scan monitoring system, initially introduced in the hydrogen production process, to other processes. This system provides real-time monitoring of furnace conditions, enabling AI-driven optimization of operating parameters. Traditionally, furnace conditions were monitored and adjusted manually by operators. However, AI-based automation is expected to enhance operational efficiency while reducing fuel consumption and carbon emissions.

GS Caltex and its project partners anticipate that this initiative will significantly improve productivity for petrochemical companies within the Yeosu National Industrial Complex. As the global petrochemical industry faces prolonged challenges due to oversupply from China and weakened global demand, AI-driven process optimization presents a crucial opportunity to reduce production costs, enhance operational efficiency, and improve profitability. Furthermore, the project is expected to accelerate digital transformation among local businesses, creating new job opportunities and revitalizing the regional economy.

Prior to launching this national project, GS Caltex has been continuously integrating AI technologies at its Yeosu plant.

To optimize manufacturing processes, the company developed its own AI models to enhance refinery operations, increasing the production of high-value-added products. AI-driven optimization systems have also been applied to the naphtha cracking process to improve economic efficiency and to the hydrogen production process to boost output.

In terms of safety innovation, GS Caltex has deployed AI-powered CCTV systems to detect potential hazards in real time. It has also established VR (Virtual Reality) and MR (Mixed Reality) safety training facilities to enhance employee safety awareness. Drones are utilized for inspections in high-altitude and confined spaces, while wireless gas detectors have been introduced to improve worker safety.

Furthermore, to enhance equipment management and logistics efficiency, GS Caltex has implemented an AI-based vibration analysis system to ensure the reliability of rotating machinery. The company has also developed a proprietary mobile app to systemize and streamline product shipment operations, which were previously conducted via telephone.

For its efforts in AI-driven manufacturing process optimization, safety innovation, and efficiency improvements in equipment management and logistics, GS Caltex was honored with the Minister of Trade, Industry, and Energy Award in December last year for its contributions to digital transformation.

A GS Caltex representative stated, “With our continued application of AI technology and the advancement of the AI autonomous manufacturing platform, we are accelerating our digital transformation. We are committed to leveraging these innovations to achieve sustainable and profitable growth as we move towards our vision of becoming a century-old enterprise.”

![[에너지 숏터뷰] 글로벌 고객과 함께한 GS칼텍스 Customer Appreciation Night 2024🌠 7 [에너지 숏터뷰] 글로벌 고객과 함께한 GS칼텍스 Customer Appreciation Night 2024🌠 | TH F](http://3.39.152.22/wp-content/uploads/2024/06/TH_F.jpg)